To ELLWOOD National Forge, providing our customers with world-class product solutions isn’t an option, it’s our guarantee.

Headquartered in Irvine, Pennsylvania, ELLWOOD National Forge, was formerly the National Forge Company that was founded in 1915 by Clinton E. Wilder and others. Originally located in Erie, Pennsylvania, National Forge moved its operations to Irvine, Pennsylvania in 1917 where they held various equipment and process patents for deep-hole shaft boring and trepanning. Throughout the 1920’s – 1980’s National Forge participated in a variety of specialty commercial and defense markets including the production of crankshafts, steel pipe molds, ordnance components, submarine propulsion shafting, and power generation rotors.

In 2003, ELLWOOD acquired the assets of the National Forge Company and was reborn as ELLWOOD National Forge. ELLWOOD is a family company founded in 1910 by David A. Evans and his brother, Jonathan A. Evans. All of the common stock remains in the hands of some 35 family members. David Evans Barensfeld, Chairman of the Board of Directors and controlling shareholder, was the fifth family member to hold the office of President and CEO. He occupied that post from 1983 until 2019, when he was succeeded by Bentraum D. Huffman.

ELLWOOD’s private status permits us to operate independently of short-term perspectives while acting to maximize long-term values of product quality and customer service. This long-term orientation has, for decades, made us a preferred workplace for employees. ELLWOOD wants its people to have the best tools, so ELLWOOD reinvests profits constantly to buy newer, safer, and more productive equipment. Our customers are the world’s leading manufacturers of capital equipment.

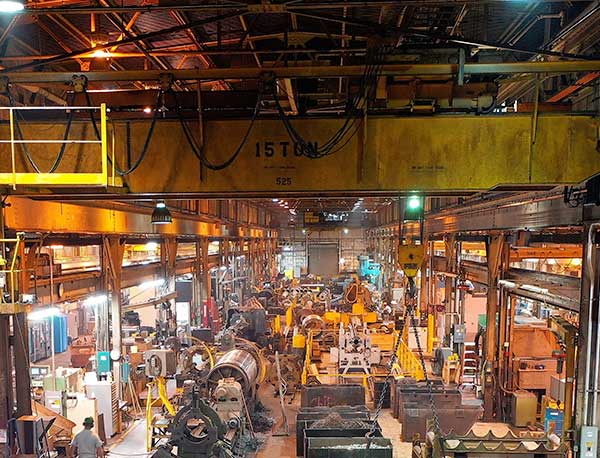

Today ELLWOOD National Forge has three facilities, with a total of over 600,000 sq ft of manufacturing space. ELLWOOD National Forge is a leader in forging, heavy machining and project management of products for defense, oil & gas, power generation, and heavy industrial markets. We have continued our legacy in specializing in precision boring, turning, and heat treatment of large forgings. ELLWOOD National Forge’s experienced employees specialize in a wide range tight-tolerance finish machined products with high length/width ratios and finished bored interior diameters. With in-house estimating, engineering, metallurgy and project management, ELLWOOD National Forge has a unique ability to manage complex projects throughout the entire melting, forging, and finish machining processes.